Washington Township Waste Authority SBR

Barto, Washington Township, Berks County, PA

Washington Township Waste Authority SBR

Barto, Washington Township, Berks County, PA

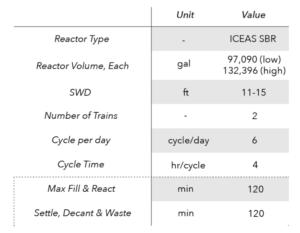

The Washington Township Waste Authority (WTWA) SBR is a two train, 250,000 GPD SBR process with 4-hr cycle times. In March 2020, WTWA installed Nuvoda’s MOB Process in one of the two trains. Over the course of a ten month trial, a significantly increased flow through the MOB Process train was used to test and demonstrate the MOB Process’ ability to handle both increased flow and peak flow events(> 1 Ox design). Results showed the MOB Process in the SBR was capable of handling up to 70% increased flow above design while maintaining effluent discharge requirements, and in the case of phosphorus, lowering effluent levels at increased flow. Furthermore, the MOB Process also handled the very high peak flow events(> 1 Ox design) while maintaining effluent TSS levels and clarity.

PROJECT BACKGROUND

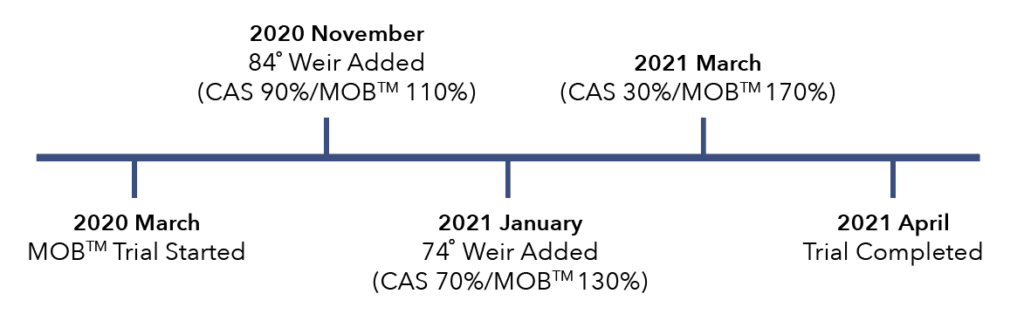

Throughout the trial, the WTWA SBR have collaborated with Nuvoda to conduct sample collections and effluent quality tests twice a week. During the trial, the Washington Township Waste Authority SBR conducted flow diversion with weirs to slowly increase flow distribution into the MOB Process train (from rated capacity to 70% increase over rated capacity). These process changes were recorded and presented in this report. The unchanged SBR will be labeled as “CAS” (Conventional Activated Sludge), and the MOB trial SBR will be labeled as “MOB”.

PROCESS CHANGE TIMELINE

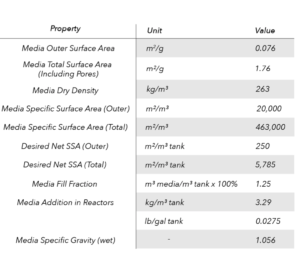

SBR SPECIFICATION MOB PROCESS DESIGN PARAMETERS

TRIAL DATA & ANALYSIS

PEAK FLOW PERFORMANCE COMPARISON

SETTLING AND WASHOUT PREVENTION

Despite an increase of capacity of 170% through the MOB SBR, the process was able to consistently demonstrate a sludge volume index (SVI) below 80 mg/L. In addition to settling, the MOB ballast prevented MLSS washout during peak flow conditions, ultimately avoiding the loss of nitrification and improved effluent. Evidence of the washout prevention can be observed in Section C of Effluent Quality Comparison Images.

PHOSPHORUS REMOVAL

The MOB Process demonstrated Total nitrogen< 7.0 mg/L and Total Phosphorus concentrations < 1 mg/L throughout most of the trial despite a 170% increase in capacity. Both nutrient concentrations were well below permitted values and would provide sufficient data for a process rerate which would double capacity.

Call: (919) 615 – 1205 | Email: sales@nuvodaus.com